How To Properly Replace Galvanized Steel Roofing Cap

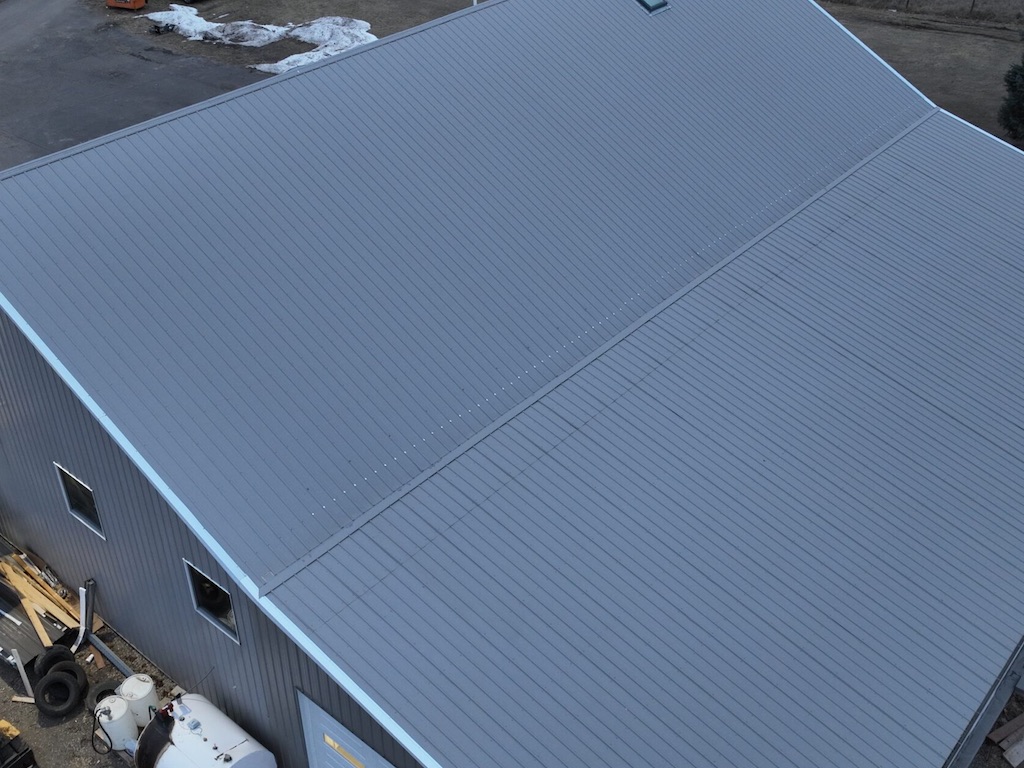

Hey guys, good to see you again. Spencer Hall with Endurance Exteriors. The red, white and blue. And as you know, these colors do not run. And what am I doing up here in the sky except for yapping about a roof. Metal Roofing Cap So let’s get right into it today. I’m going to talk to you about the metal cap that we put at the top of this after the shingles were put on. But before we do that, let’s talk about what it used to be. Galvanized steel before, yes, but in poor condition. And when we tore it off, we discovered underneath that the wood had rotten and was not that good. Ice and Water Roofing Materials So we laid down a plywood sheet and followed by ice and water shielding, followed by the metal cap that you see here now. Now let’s get into the metal cap. This is galvanized steel standing steam style roofing. And you can tell by the grooves here, right? 26 gauge standing seam. And you can notice that it’s kind of put on in a pizza slice kind of fashion. It wasn’t one single metal piece. It’s actually individual slices that got put together to form the greater dome shape. Now this is for two reasons. First of all, it helps disperse snow. It’s not going to sit up here. It’s an esthetic piece, but from the ground most people can’t see it. It’s going to allow water to run off more cleanly. And we also hid a lot of fasteners in here that you can’t see to provide a more esthetic look. The cross is pre existing still in great condition. So we reuse that. And as you can see on the sides here, it’s got kind of a lip. And that lip is meant to also disperse water more efficiently. So 26 gauge standing seam metal pizza slice formation, ice and water beneath and also plywood sheets. And we kept the same cross and that’s the metal dome. Pro Tips Always follow the manufacturer’s specific instructions for your new cap, as details can vary. When overlapping multiple pieces of metal, always ensure the upper piece overlaps the lower piece in the direction of water flow to maintain a watertight seal. If the cap is installed under shingles, use a prybar to gently loosen and remove nails under the footprint of the existing cap flange. For metal-to-metal installations, unscrew the existing fasteners. If screws are rusted, you may need a lubricant or an impact driver. Remove old roof cement, debris, and sealant from the roof surface and the protruding duct to ensure a watertight seal for the new unit. Safety First Check the weather: Ensure the weather is dry and calm during the entire process. Work safely: Use a sturdy ladder, and consider a safety harness if working on a sloped roof. Wear protective gear: Use work gloves and eye protection when cutting and handling metal or using tools. View the full video on our Facebook page.

New Roofing Technology Trends Transforming the Industry

The roofing industry is experiencing a technological revolution that’s changing how we protect, power, and maintain our homes and buildings. From solar integration to smart sensors, these innovations are making roofs more durable, efficient, and environmentally friendly than ever before. Whether you’re a homeowner planning a roof replacement or a contractor looking to stay ahead of the curve, understanding these cutting-edge roofing technologies is essential. In this comprehensive guide, we’ll explore nine groundbreaking roofing technology trends that are reshaping the industry and what they mean for your next roofing project. Solar Roofing Integration: Beyond Traditional Panels Solar roofing technology has evolved dramatically from the bulky panels of the past. Today’s solar roofing solutions seamlessly integrate photovoltaic technology directly into roofing materials, creating a sleek, efficient energy-generating surface. Solar Shingles and Tiles Solar shingles represent a major leap forward in residential solar technology. Unlike traditional solar panels that sit on top of your existing roof, solar shingles replace conventional roofing materials entirely. These innovative products look remarkably similar to standard asphalt or slate shingles while generating clean electricity for your home. The latest solar shingles offer improved efficiency ratings, with some products converting up to 22% of sunlight into usable electricity. They’re also more durable than ever, with warranties extending 25 years or more. For homeowners concerned about aesthetics, solar shingles provide a low-profile alternative that maintains curb appeal while reducing energy costs. Building-Integrated Photovoltaics (BIPV) Building-integrated photovoltaics take solar integration even further. BIPV systems incorporate solar technology into the building envelope itself, turning the entire roof into a power-generating surface. These systems are particularly popular in commercial construction, where large roof surfaces can generate substantial amounts of electricity. The financial benefits of solar roofing continue to improve as well. Federal tax credits, state incentives, and declining installation costs make solar roofing more accessible than ever. Many homeowners see a return on investment within 7-12 years, with decades of free electricity to follow. Cool Roofing Technology: Reflecting Heat and Saving Energy Cool roofing technology uses highly reflective materials to minimize heat absorption, keeping buildings cooler and reducing air conditioning costs. This trend has gained significant momentum as energy efficiency becomes increasingly important for both environmental and economic reasons. Advanced Reflective Coatings Modern cool roof coatings utilize advanced infrared-reflective pigments that bounce solar radiation back into the atmosphere before it can heat your building. These coatings can be applied to various roofing materials, including metal, single-ply membranes, and even asphalt shingles. The results are impressive. Cool roofs can reduce surface temperatures by 50-60 degrees Fahrenheit compared to traditional dark roofing materials. This translates to significant energy savings, with many building owners reporting 10-30% reductions in cooling costs. Cool Roof Color Technology Historically, achieving maximum reflectivity meant choosing light-colored or white roofing. However, new pigment technologies allow manufacturers to create cool roof products in darker colors, including grays, blues, and even blacks. This innovation gives property owners more design flexibility without sacrificing energy efficiency. The environmental benefits extend beyond individual buildings. Cool roofs help reduce the urban heat island effect in cities, where concentrated dark surfaces raise ambient temperatures. This community-level benefit has led many municipalities to encourage or require cool roofing in new construction and renovation projects. Drones and Aerial Inspection Technology Drone technology has revolutionized roof inspections, making them safer, faster, and more accurate than traditional methods. Roofing contractors are increasingly adopting drones equipped with high-resolution cameras and thermal imaging sensors to assess roof conditions without risking worker safety. Enhanced Safety and Efficiency Traditional roof inspections require workers to climb onto potentially damaged or unstable structures, creating safety risks. Drones eliminate this danger while providing more comprehensive data. A drone can capture detailed images of an entire roof in minutes, compared to hours of manual inspection time. Modern roofing drones carry sophisticated camera systems that capture 4K video and high-resolution photos. These images can be analyzed immediately or archived for future comparison, making it easier to track roof deterioration over time. Thermal Imaging and Moisture Detection Advanced drones equipped with thermal imaging cameras can detect moisture infiltration, insulation gaps, and heat loss that aren’t visible to the naked eye. This technology identifies problems early, before they cause serious damage, saving property owners thousands in repair costs. The data collected by drones also improves estimate accuracy. Contractors can measure roof dimensions, calculate material quantities, and identify potential challenges without multiple site visits. This efficiency reduces project costs and speeds up the bidding process. Smart Roofing Systems with IoT Sensors The Internet of Things (IoT) has reached the roofing industry, bringing smart monitoring capabilities that provide real-time data about roof performance and condition. Smart roofing systems use networks of sensors to detect leaks, monitor structural integrity, and alert property owners to potential problems. Leak Detection Sensors Water intrusion is one of the most destructive roofing problems, often causing extensive damage before it’s noticed. Smart leak detection sensors can identify moisture within minutes of intrusion, triggering immediate alerts via smartphone apps or building management systems. These sensors are particularly valuable in commercial buildings, where large roof surfaces make visual inspection challenging. Early leak detection prevents secondary damage to inventory, equipment, and building interiors, potentially saving hundreds of thousands of dollars. Environmental Monitoring Advanced smart roofing systems monitor multiple environmental factors, including temperature, humidity, wind speed, and UV exposure. This data helps property owners optimize HVAC performance and predict maintenance needs based on actual roof stress rather than arbitrary schedules. For building managers overseeing multiple properties, cloud-based dashboards aggregate data from all locations, providing a comprehensive view of roofing system performance across their entire portfolio. This centralized monitoring improves maintenance planning and budget forecasting. Sustainable and Recycled Roofing Materials Environmental consciousness is driving innovation in roofing materials, with manufacturers developing products from recycled content and renewable resources. These sustainable options deliver comparable or superior performance to traditional materials while reducing environmental impact. Recycled Rubber and Plastic Shingles Recycled rubber shingles, often made from reclaimed tires, offer exceptional durability and weather resistance. These products can

How To Prepare Commercial Roofs For Winter

Winter weather poses serious threats to commercial roofing systems. From heavy snow accumulation and ice dams to freeze-thaw cycles and severe temperature fluctuations, the cold season tests every aspect of your roof’s integrity. Property managers and building owners who prioritize winter roof preparation can prevent costly emergency repairs, protect their investments, and ensure tenant safety throughout the harshest months. This comprehensive guide covers essential winterizing techniques that every commercial property should implement before winter arrives. Whether you manage office buildings, warehouses, retail centers, or multi-family properties, these proven strategies will help your roof withstand whatever winter throws at it. Understanding Winter’s Impact on Commercial Roofs Before diving into winterization techniques, it’s important to understand the specific challenges winter weather creates for commercial roofing systems. Snow Load Accumulation. Commercial flat and low-slope roofs are particularly vulnerable to snow accumulation. A cubic foot of fresh snow weighs approximately 7 pounds, while packed snow can weigh up to 20 pounds per cubic foot. Ice weighs even more at 57 pounds per cubic foot. This significant weight can strain roof structures, especially when snow accumulates unevenly or creates drifts. Ice Dam Formation. Ice dams occur when heat escaping from the building melts snow on the roof. The water runs down to colder areas near the roof edge and refreezes, creating a dam that prevents proper drainage. Water backs up behind these ice barriers and can seep under roofing materials, causing leaks and water damage. Freeze-Thaw Cycles. Temperature fluctuations cause materials to expand and contract repeatedly. Water that enters small cracks or seams freezes and expands, widening those openings. When it melts, more water enters the enlarged gap, and the cycle continues. This process can rapidly deteriorate roofing materials and create significant leak points. Wind Damage. Winter storms bring powerful winds that can lift roofing membranes, tear off flashing, and send debris onto your roof. Cold temperatures make roofing materials more brittle and susceptible to wind damage. Reduced Material Flexibility. Most roofing materials become less flexible in extreme cold. This increased rigidity makes them more prone to cracking, tearing, and puncturing during winter months. Conducting a Comprehensive Pre-Winter Roof Inspection Membrane Condition Assessment. Examine the entire roof membrane for signs of wear, aging, or damage. Look for cracks, tears, blistering, punctures, or areas where the membrane has separated from the substrate. Pay special attention to high-traffic areas and spots where equipment or penetrations are located. Any compromised areas should be repaired before winter arrives. Seam and Joint Inspection. Seams are common failure points on commercial roofs. Inspect all seams carefully for separation, gaps, or deterioration. On TPO and PVC roofs, check that heat-welded seams are fully bonded. For EPDM roofs, verify that tape or adhesive seams are intact without lifting or peeling edges. Flashing Examination. Flashing around roof penetrations, parapet walls, edges, and transitions between different roof levels must be secure and properly sealed. Look for loose or missing flashing, deteriorated caulk, gaps, or rust on metal flashing. Flashing failures are a leading cause of winter roof leaks. Fastener and Attachment Review. On mechanically attached roof systems, inspect fasteners for loosening, corrosion, or areas where they may have backed out. Check that membrane remains properly secured around all fasteners. Loose fasteners create openings for water infiltration and wind can more easily damage poorly secured membrane sections. Drain and Scupper Inspection. Verify that all drains, scuppers, overflow drains, and downspouts are clear of debris and functioning properly. Check drain strainers, make sure they’re secure, and confirm that drain boots and seals around drain penetrations are intact. Test drainage by running water to ensure it flows freely without pooling. Gutter and Downspout Evaluation. Clean gutters and downspouts thoroughly, removing leaves, debris, and any obstructions. Check for proper pitch to ensure water flows toward drains. Inspect gutter attachments and supports to verify they can handle the weight of ice and snow. Repair or replace damaged gutter sections. Parapet and Edge Assessment. Inspect parapet walls for cracks, deterioration, or damage to copings and caps. Verify that edge metal and gravel stops are securely fastened. Check that counterflashing is properly installed and sealed. Penetration Sealing Review. Examine all roof penetrations including HVAC units, pipes, vents, skylights, and access hatches. Verify that seals and boots around these penetrations are intact without cracks or gaps. Even small openings can allow water infiltration during winter weather. Insulation and Ventilation Check. Proper insulation and ventilation prevent heat loss that contributes to ice dam formation. Inspect accessible insulation for adequate R-value, damage, or moisture infiltration. Verify that ventilation systems are functioning correctly. Structural Evaluation. Look for signs of structural stress including sagging areas, standing water, or evidence that previous snow loads caused problems. If you notice concerning structural issues, consult with a structural engineer before winter. Critical Repairs and Preventive Maintenance Once your inspection identifies issues, address them promptly. Some repairs are particularly critical before winter arrives. Seal All Leaks and Vulnerable Areas. Repair any areas where water could penetrate. Use appropriate materials for your roof type. Apply roof coatings or sealants to small cracks or worn areas. For larger damage, patch or replace affected membrane sections. Don’t attempt temporary fixes for significant damage—proper repairs now prevent major problems during winter. Secure Loose Materials. Reattach any loose membrane, flashing, or edge metal. Add fasteners where needed on mechanically attached systems. Ensure all roof components are properly secured to withstand winter wind forces. Replace Deteriorated Caulk and Sealants. Remove old, dried, or cracked caulk around penetrations, terminations, and flashing. Apply fresh, high-quality sealant appropriate for cold weather performance. Pay special attention to areas around HVAC equipment and pipe penetrations. Repair or Replace Damaged Flashing. Don’t compromise on flashing repairs. Properly install new flashing where needed, ensuring it’s correctly sealed and secured. This investment prevents water infiltration during snowmelt events. Upgrade Inadequate Drainage. If your inspection revealed drainage problems, address them before winter. Add additional drains or scuppers if needed. Ensure positive drainage across the entire roof surface. Consider installing secondary overflow drains in areas prone to water accumulation. Reinforce